Services

Complete Aerospace Manufacturing Services Built for Complex Challenges

When aerospace professionals need a partner who understands that “good enough” isn’t good enough, they turn to ACMT’s comprehensive aerospace manufacturing services. Since 1986, we’ve built our reputation on one simple principle: if it’s complex, challenging, or mission-critical, we’re the team you want in your corner.

From our flagship campus in Manchester, Connecticut, we’ve grown from a specialized repackaging operation into a global aerospace leader serving commercial, military, and rotor aircraft markets. But here’s what hasn’t changed—our commitment to quality, reliability, and the kind of flexibility that turns manufacturing headaches into success stories.

Turnkey Solutions That Actually Work

The aerospace industry doesn’t need another vendor making promises they can’t keep. What you need is an aerospace turnkey manufacturer who can handle your project from initial concept through final delivery—and still be there when you need support down the line.

Our aerospace turnkey solutions approach means you get one point of contact, one quality standard, and one team committed to your success. Whether you’re dealing with a single custom component or a complex multi-phase assembly, we’ve got the engineering expertise, manufacturing capabilities, and quality systems to make it happen.

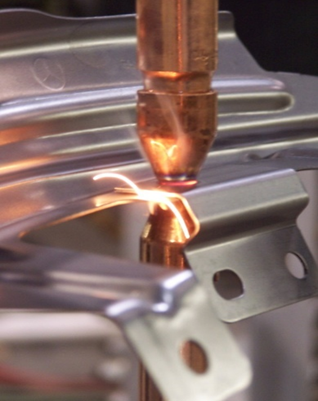

OEM Component Fabrication: Precision Meets Innovation

Our OEM capabilities span everything from simple brackets to complex assemblies that push the boundaries of what’s possible. We specialize in aerospace parts manufacturing for:

- Sheet Metal Components: Brackets, covers, structural elements, and airframe components using aluminum, Inconel, steel, and titanium

- Complex Assemblies: LPC compressor stator assemblies, fan exit guide vanes, seals, and liners

- Specialized Fabrication: Leading edges for rotor blades, air guide vanes, and aerostructures requiring precise tolerances

What sets us apart? Our investment in cutting-edge aerospace manufacturing technologies. But technology alone doesn’t make great parts, it’s how our engineers apply that technology to solve your specific challenges.

Maintenance, Repair & Overhaul: Keeping You Flying

When components need more than routine maintenance, our MRO division steps in with FAA-certified expertise (Certificate # H03R013Y) and dual FAA/EASA release capabilities. We handle everything from fan modules to low pressure compressor components across major engine types including:

- ALF502, CF6-80 series, CFM56 family

- PW2000, PW4000, PW6000

- V2500 variants and military applications

Our MRO process isn’t just about fixing what’s broken—it’s about collaborative problem-solving. We work with you to understand not just the immediate repair needs, but how to prevent future issues and extend component life.

Advanced 3D Printing: Rapid Solutions for Complex Needs

Our Fortus 450 3D printer brings rapid prototyping and tooling capabilities directly to your projects. Using engineering-grade thermoplastics including ABS-M30, polycarbonate, and Ultem materials, we create:

- Functional prototypes with exacting tolerances

- Custom tools and gauges

- Complex geometries that traditional manufacturing can’t achieve

This isn’t just about speed—it’s about giving you the flexibility to iterate, test, and perfect your designs without the traditional constraints of conventional manufacturing.

Specialized Adhesives & Chemical Solutions

Sometimes the most critical components are the ones you can’t see. Our in-house laboratory formulates and packages specialty adhesives and chemicals that meet the demanding requirements of aerospace applications:

- Epoxies for bonding and sealing applications

- Urethanes and Silicones for specialized sealing needs

- Primers and Specialty Reagents tested to OEM specifications

- Custom Packaging from 10cc syringes to 5-gallon containers

Every batch is tested and certified in our dedicated laboratory, with lot traceability and re-certification services to extend shelf life and reduce waste.

Quality That Never Compromises

Our certifications tell the story: AS9100, FAA repair station, NADCAP welding and FPI, ISO 9001. But the real quality story is in our eight state-of-the-art CMMs, automated blue light inspection stations, and PWA104 A&B clean rooms with sophisticated environmental controls.

We’re one of only four original GTF family FAA-approved repair stations, and we maintain Pratt & Whitney Engineering Source Approval (ESA) and Repair Source Approval (RSA) status. These aren’t just certificates on the wall—they’re proof that when aerospace OEMs need partners they can trust, they choose ACMT.

Ready to Solve Your Next Challenge?

Whether you’re facing a complex manufacturing challenge, need reliable MRO support, or want to explore how advanced manufacturing technologies can improve your products, we’re here to help. Our team combines decades of aerospace experience with a forward-looking approach that embraces innovation while respecting the critical nature of what we build.

Contact Us!