Aerospace

Aerospace Manufacturing Industry: Where Innovation Meets Excellence

For nearly four decades, ACMT has been the aerospace components manufacturer that industry leaders turn to when standard solutions aren’t enough. In an aerospace manufacturing industry where precision, reliability, and innovation determine success, we’ve built our reputation by consistently delivering aerospace solutions that exceed expectations across commercial, military, and rotor aircraft applications.

What started as a clean room repackaging operation in 1986 has evolved into a comprehensive aerospace manufacturing powerhouse. Today, we leverage advanced aerospace manufacturing technologies to tackle the complex challenges that define modern aviation – from intricate aircraft part fabrication to precision aerospace machining that meets the most demanding specifications.

Our Role in Advancing Aerospace Manufacturing Technologies

At ACMT, we don’t just keep pace with aerospace manufacturing technologies – we help define them. Our investment in state-of-the-art equipment creates capabilities that solve problems others can’t touch. When aerospace professionals need precision aerospace machining for titanium components or complex aircraft part fabrication for next-generation engines, they know ACMT delivers.

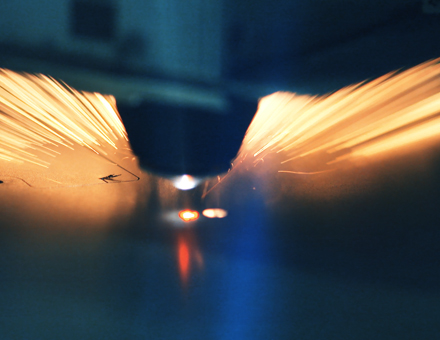

Our TRUMPF Auto Bend Cell and flat pattern laser systems represent the cutting edge of sheet metal fabrication. Combined with our Omax 5-axis water jet cutting capabilities, these aerospace manufacturing technologies enable us to produce components with tolerances that push the boundaries of what’s possible.

But technology alone doesn’t create excellence. Our GOM Blue Light scanners and eight state-of-the-art CMMs provide the precision measurement capabilities that ensure every component meets aerospace industry standards. This integration of advanced equipment with rigorous quality control makes ACMT the aerospace components manufacturer that OEMs trust with their most critical projects.

Comprehensive Aerospace Solutions Across All Sectors

Commercial Aviation Excellence ACMT serves the commercial aerospace manufacturing industry with components that keep global fleets flying safely and efficiently. As a FAA Part 145 certified repair station (H03R013Y) with both FAA and EASA dual release capabilities, we provide aerospace solutions that meet the stringent requirements of commercial aviation.

Our expertise in aircraft part fabrication extends across major engine families including CFM56, PW4000, V2500, and CF6 series. From fan exit guide vanes to LPC compressor stator assemblies, our precision aerospace machining capabilities ensure components perform flawlessly across millions of flight hours.

Military Aerospace Manufacturing Supporting military applications requires an aerospace components manufacturer that understands the unique demands of defense contracting. ACMT delivers aerospace solutions for today’s military aircraft through direct supply to the Department of Defense and prime contractors.

Our aerospace manufacturing technologies handle exotic materials like Inconel and titanium with the precision and security protocols military applications demand. Whether it’s complex assemblies or specialized repairs, we provide the aircraft part fabrication capabilities that keep military fleets mission-ready.

Rotor Aircraft Innovation The rotor aircraft segment presents unique challenges that showcase ACMT’s adaptability as an aerospace components manufacturer. Our consolidated approach brings specialized processes under one roof, enabling us to handle everything from 20-foot rotor blade leading edges to complex airframe assemblies.

Our precision aerospace machining capabilities extend to components that must withstand the unique stress patterns of rotary-wing flight. From abrasion strips to structural assemblies, we deliver aerospace solutions that meet the demanding requirements of helicopter and rotorcraft applications.

Advanced Aircraft Part Fabrication Capabilities

ACMT’s aircraft part fabrication capabilities span the full spectrum of aerospace manufacturing. Our hydroforming technology creates complex shapes from aluminum, steel, and titanium with the precision that aerospace applications demand. This aerospace manufacturing technology enables us to produce parts with superior strength-to-weight ratios while maintaining the exact tolerances required for safe flight.

Our titanium hot forming capability sets us apart in the aerospace manufacturing industry. Working with titanium requires specialized knowledge and equipment – ACMT has both. Our custom-configured atmosphere booths and precise temperature control systems ensure titanium components meet the exacting standards of aerospace applications.

Composite bonding represents another area where ACMT excels as an aerospace components manufacturer. Our PWA104 A&B clean rooms provide the controlled environment necessary for bonding rubber to metal, rubber to composite, and advanced epoxy applications. These aerospace solutions enable the lightweight, high-performance structures that define modern aircraft design.

Precision Aerospace Machining Excellence

Our precision aerospace machining capabilities encompass everything from traditional turning and milling to advanced laser cutting and water jet applications. ACMT’s machining centers handle complex geometries with the accuracy that aerospace manufacturing demands – often working to tolerances measured in thousandths of inches.

What makes our precision aerospace machining different? It’s the combination of advanced equipment with experienced operators who understand aerospace requirements. Our machinists don’t just follow prints – they understand how each component fits into larger assemblies and how manufacturing decisions impact final performance.

Our laser part marking and engraving capabilities ensure traceability throughout the aerospace supply chain. From simple part numbers to complex 2D matrix codes, we provide the marking solutions that keep components traceable from manufacturing through service life.

Quality Systems That Define Aerospace Excellence

As an aerospace components manufacturer, ACMT operates under the most rigorous quality standards in the industry. Our AS9100 and ISO certifications provide the framework, but our commitment to continuous improvement drives us beyond baseline requirements.

Our Pratt & Whitney Engineering Source Approval (ESA) and Repair Source Approval (RSA) certifications demonstrate the trust major OEMs place in our capabilities. These approvals mean we don’t just meet aerospace manufacturing industry standards – we help establish them.

Our in-house laboratory capabilities support both metallic and non-metallic testing to ASTM and MCL standards. This enables us to provide aerospace solutions with complete material certification and traceability. When aerospace professionals need confidence in component performance, they turn to ACMT.

Specialized Aerospace Solutions

MRO Services ACMT’s maintenance, repair, and overhaul capabilities keep commercial and military fleets flying. Our fully equipped repair shop handles everything from traditional repairs like welding and machining to innovative approaches like composite patching and advanced coatings.

Our SPOP cleaning capabilities and comprehensive tear-down and reassembly services ensure components return to service in like-new condition. This aerospace manufacturing expertise extends component life and reduces lifecycle costs for our partners.

Adhesives and Chemicals As a specialty aerospace components manufacturer, ACMT formulates and supplies aerospace-grade adhesives and chemicals tested to OEM specifications. From epoxies and urethanes to silicones and primers, we control quality from formulation through final delivery.

Our dedicated laboratory enables us to extend shelf life through lot tracing and re-certification, providing aerospace solutions that reduce waste and improve inventory management for our partners.

3D Printing and Rapid Prototyping Our Fortus 450 3D printer enables rapid prototyping and tool fabrication with engineering-grade thermoplastics including Ultem 1010 and 9085. This aerospace manufacturing technology accelerates development cycles and enables cost-effective tooling solutions.

Partnership Approach to Aerospace Excellence

What sets ACMT apart in the aerospace manufacturing industry is our partnership approach to problem-solving. We don’t just manufacture components – we collaborate with aerospace professionals to develop solutions that address real-world challenges.

Our engineering team works closely with customers from concept through production, providing the technical expertise that turns complex requirements into manufacturable solutions. This collaborative approach has enabled us to develop everything from specialized repair processes to entirely new manufacturing methods.

Your Aerospace Manufacturing Partner

The aerospace manufacturing industry demands partners who understand that excellence isn’t negotiable. At ACMT, we’ve built our reputation by consistently delivering aerospace solutions that exceed expectations while maintaining the flexibility to adapt to changing requirements.

Whether you need complex aircraft part fabrication, precision aerospace machining, or comprehensive MRO services, ACMT brings the expertise and commitment to quality that keeps your projects moving forward. Our aerospace manufacturing technologies and experienced team are ready to tackle your most challenging requirements.

Our engineering team works closely with customers from concept through production, providing the technical expertise that turns complex requirements into manufacturable solutions. This collaborative approach has enabled us to develop everything from specialized repair processes to entirely new manufacturing methods.

Contact Us!