Rotor Aircraft

Leading Solutions for Rotor Aircraft Manufacturers

When rotor aircraft manufacturers face complex fabrication challenges, they turn to partners who understand that precision isn’t just preferred—it’s paramount. At ACMT, we’ve built our reputation by solving the intricate problems that keep rotorcraft flying safely and efficiently. From abrasion strips that can handle 20-foot blade lengths to complete airframe assemblies, we bring together decades of aerospace expertise with cutting-edge technology to deliver solutions that simply work.

A Partnership Approach to Rotorcraft Excellence

The rotorcraft industry operates in a world where every component must perform flawlessly under extreme conditions. Whether you’re developing next-generation tilt rotor aircraft solutions or maintaining legacy fleets, you need a manufacturing partner who understands the unique demands of vertical flight. That’s where our story begins.

We developed our rotorcraft capabilities not through accident, but through purposeful strategy. Recognizing the specialized nature of rotor aircraft manufacturing, we made the commitment to consolidate the unique fabrication processes under one roof. This approach allows us to maintain the precision and quality control that rotorcraft demand while offering the flexibility that modern manufacturers require.

Our in-house expertise spans the full spectrum of rotorcraft component fabrication. We handle everything from sheet metal forming up to 20 feet in length to complex rubber composite components. This comprehensive capability means you’re working with one trusted partner throughout your entire project lifecycle, rather than managing multiple vendors across different specialties.

Advanced Manufacturing Capabilities for Modern Rotorcraft

Precision Machining for Rotorcraft That Exceeds Expectations

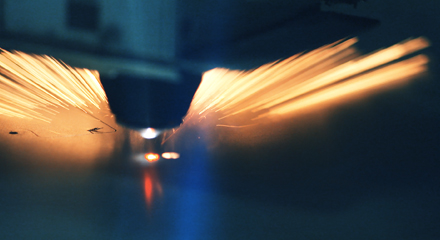

The precision machining for rotorcraft that we deliver goes far beyond standard tolerances. Our state-of-the-art equipment includes TRUMPF laser cutting systems, Omax 5-axis water jet cutting, and advanced CNC capabilities that ensure every component meets the exacting standards rotorcraft demand. But technology alone doesn’t guarantee success—it’s the combination of advanced equipment with experienced engineers who understand the unique stresses and requirements of vertical flight.

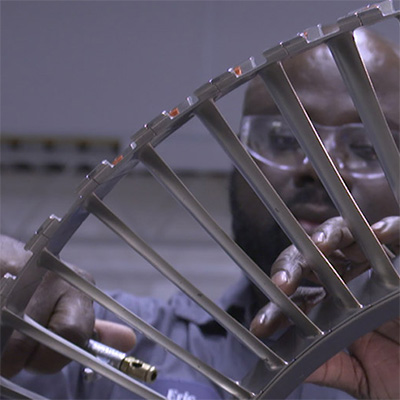

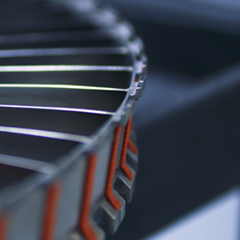

Take our abrasion strip fabrication capability as an example. We can handle blade lengths up to 20 feet, performing both hot and cold forming on titanium alloy with the precision that rotor blade applications require. This isn’t just about having the equipment—it’s about understanding the aerodynamic and structural demands that make rotorcraft so challenging to manufacture.

Contract Manufacturing for Rotor Aircraft Excellence

Our contract manufacturing for rotor aircraft encompasses the full range of components and assemblies that keep rotorcraft operational. From firewalls and air inlet ducts to window frames and door assemblies, we approach each project with the understanding that rotorcraft components face unique challenges that fixed-wing aircraft simply don’t encounter.

The manufacturing processes we’ve refined include welding, riveting, bonding, and complex assembly work. Each process is backed by our AS9100 certification and supported by dedicated clean rooms that maintain the environmental controls critical for aerospace applications. When you’re dealing with the complex geometries and tight tolerances that rotorcraft require, these controlled environments aren’t luxuries—they’re necessities.

Innovation Meets Tradition in Rotorcraft Solutions

Hot and Cold Forming Excellence

Our hot and cold forming capabilities represent the intersection of traditional metalworking expertise and modern precision. For rotorcraft applications, this means we can shape complex geometries while maintaining the material properties essential for safe flight operations. Whether you’re working with titanium, aluminum, or specialized alloys, our forming processes deliver the consistency and reliability that rotorcraft manufacturers demand.

The chemical cleaning and stress relief capabilities we maintain for components up to 20 feet in length ensure that every part we deliver meets not just dimensional specifications, but also the metallurgical requirements that make rotorcraft components trustworthy under stress.

Specialized Composite and Rubber Solutions

Rotorcraft manufacturing increasingly relies on advanced materials that offer superior performance characteristics. Our bonding capabilities for rubber-to-metal and rubber-to-composite applications reflect our understanding of how these materials behave in the dynamic environment of vertical flight. The dedicated clean rooms we maintain for silicone, polyurethane, and epoxy work ensure that these critical bonds maintain their integrity throughout the component’s service life.

Quality Assurance That Builds Confidence

Precision Measurement and Inspection

Quality in rotorcraft manufacturing isn’t just about meeting specifications—it’s about building confidence that every component will perform when lives depend on it. Our quality assurance capabilities include eight state-of-the-art scanning CMMs, two Blue Light automated stations, and a flat pattern laser scanner. This inspection technology allows us to verify not just that components meet specifications, but that they meet them consistently, part after part.

The Keyence Vision Inspection System we employ adds another layer of precision to our quality process. For rotorcraft components where even minor variations can affect performance, this level of inspection capability provides the assurance that both we and our customers require.

Laboratory Testing and Certification

Our in-house laboratory capabilities for both metal and non-metal testing mean that quality verification happens throughout the manufacturing process, not just at the end. We perform tests to ASTM and MCL standards with experienced technicians who understand the specific requirements of rotorcraft applications. This approach to quality builds reliability into every component from the ground up.

Engineering Excellence for Complex Challenges

The engineering challenges in rotorcraft manufacturing are uniquely demanding. Unlike fixed-wing aircraft, rotorcraft must manage the complex aerodynamics of rotating systems, the structural challenges of vertical flight, and the precision requirements of components that experience rapidly changing loads. Our engineering team approaches these challenges with both deep technical knowledge and creative problem-solving capability.

We don’t just identify problems—we solve them. Our engineers work collaboratively with customers from the earliest design phases through final delivery, ensuring that manufacturing considerations are integrated into design decisions. This partnership approach means fewer surprises during production and better outcomes for everyone involved.

Your Partner in Rotorcraft Innovation

The rotorcraft industry continues to evolve rapidly, with new technologies and applications expanding the possibilities for vertical flight. From urban air mobility to advanced military applications, the demand for precision manufacturing continues to grow. At ACMT, we’re not just keeping pace with these changes—we’re helping to enable them.

Our commitment to investing in both technology and people ensures that we can support rotorcraft manufacturers as they push the boundaries of what’s possible. Whether you’re developing revolutionary new aircraft or maintaining proven platforms, we bring the flexibility, expertise, and reliability that rotorcraft manufacturing demands.

When you’re ready to experience the difference that true partnership makes in rotorcraft manufacturing, we’re ready to solve your most complex challenges. Contact us today to discover how our comprehensive capabilities can support your next project.

Contact Us!