OEM

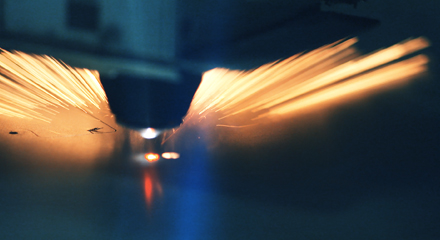

OEM Aerospace Components Manufacturers Built for Complex Challenges

When aerospace professionals face intricate fabrication challenges, they need partners who lean into complexity with excitement and expertise. That’s exactly what we bring to the table. As one of the aerospace components manufacturers you can count on, ACMT transforms your most demanding specifications into precision-engineered reality – from single custom components to complete assembly solutions.

Here’s what excites us: taking on the projects others might find too complex or specialized. Whether you’re developing next-generation rotor blade components or need titanium hot forming for critical engine applications, we approach each challenge with the same forward-looking mindset that’s driven our growth from a clean room repackaging operation to a global aerospace leader.

Comprehensive Component Fabrication Capabilities

Our component manufacturing and fabrication expertise spans the full spectrum of aerospace needs. We’ve built our reputation on adaptability and reliability, which means when you bring us a challenge, we’re already thinking three steps ahead about the best approach.

Core Fabrication Services:

- Sheet metal brackets engineered to your exact specifications

- Leading edges for rotor blades and air guide vanes

- Complex aerostructures that demand precision and durability

- Advanced surface coating applications

- Expert riveting and assembly operations

Specialized Metal Forming Technologies

What sets us apart in precision aerospace CNC machining parts manufacturers is our investment in both traditional craftsmanship and cutting-edge technology. Our titanium hot forming capabilities represent the kind of innovative approach that keeps us ahead of industry demands.

Hot & Cold Metal Forming Excellence:

- Titanium hot forming in controlled atmosphere environments

- Hot and cold metal forming across all aerospace alloys

- Custom forming solutions for unique component geometries

- Process optimization for both prototype and production runs

The beauty of our approach? We don’t just fabricate your prints, we collaborate on process improvements that can enhance both quality and efficiency. That’s the kind of partnership aerospace OEM teams appreciate.

Advanced Molding & Composite Solutions

Our molding capabilities represent years of continuous investment in both equipment and expertise. Operating from PWA104 A&B clean rooms with sophisticated humidity and temperature controls, we ensure every component meets the exacting standards of aerospace manufacturing demands.

Comprehensive Molding Services:

- Silicones, polyurethanes, epoxies, and composites

- Compression and transfer molding operations

- In-house tool design and fabrication team

- VTL rubber grinding and cutting capabilities

- Dedicated clean room environments for critical applications

What really makes the difference is our in-house tool design and fabrication team. Instead of outsourcing this critical function, we maintain complete control over tooling quality and delivery schedules. This flexibility allows us to adapt quickly when design changes emerge – and in aerospace development, they always do.

Custom Aerospace Parts with Turnkey Approach

As an aerospace part manufacturer, we understand that component fabrication is just one piece of your larger puzzle. That’s why we’ve structured our operations to serve as your complete manufacturing partner, handling everything from initial material sourcing through final inspection and delivery.

Our Turnkey Advantage:

- Single-source responsibility for complex projects

- Integrated quality systems throughout all processes

- Collaborative engineering support for design optimization

- Flexible scheduling to meet your program demands

We maintain a 30-day supply of common materials and components, which means those unexpected urgent requirements don’t become project delays. It’s this kind of forward-thinking approach that keeps our customers coming back for their most challenging programs.

Quality & Certifications You Can Trust

Quality isn’t something we add at the end – it’s built into every process from day one. Our certifications include AS9100, FAA repair authorization (H03R013Y), and NADCAP welding and FPI approvals. More importantly, we’re Pratt & Whitney engineering source approved (ESA) and repair source approved (RSA), with three DQRs completed and two additional in process.

Advanced Quality Infrastructure:

- Eight state-of-the-art scanning CMMs

- Two blue light automated inspection stations

- Flat pattern laser scanner capabilities

- In-house laboratory for comprehensive material testing

- Process control through digital work instructions and operator certification

Partner with Aerospace Manufacturing Leaders

Custom aerospace parts fabrication requires more than just technical capability – it demands a partner who understands your business challenges and responds with both urgency and precision. We’ve built our reputation on being the aerospace components manufacturers teams turn to when standard solutions won’t work.

Whether you’re launching a new aircraft program, solving a production challenge, or developing next-generation technologies, we’re ready to collaborate on solutions that exceed your expectations. Our flexibility, combined with decades of aerospace manufacturing expertise, positions us as your ideal long-term partner.

Ready to discuss your next complex fabrication challenge? Let’s explore how our capabilities align with your requirements and discover opportunities to enhance your program success.

Contact Us!